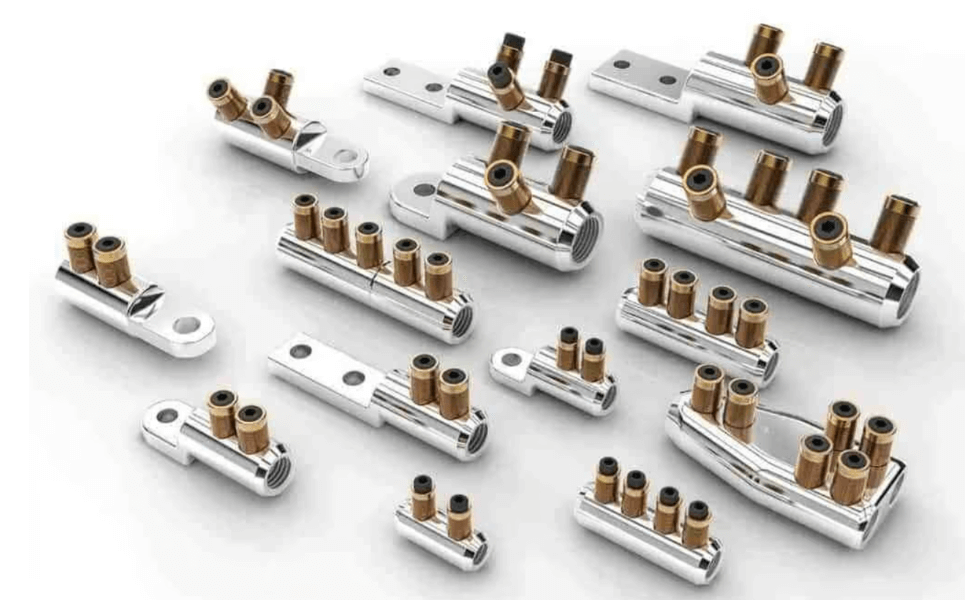

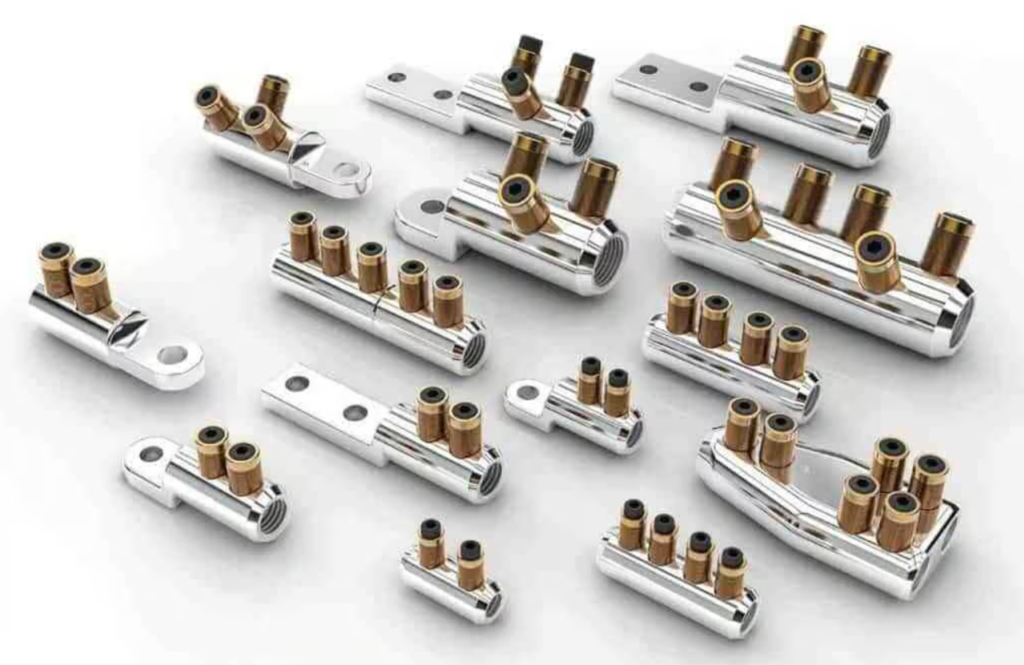

Advancements and Reliability of Medium-Voltage Shear-Off Screw (Shear-Bolt) Connectors

The screw connections have become a basic technology in electric power systems. Their design combines simplicity, reliability, and long-term mechanical and electrical stability. This article discusses the development of the MV shear off screw connectors, their fundamental benefits, the manner of their deployment in MVs, and the potential of their application to network reliability.

Origins of Shear-Bolt Technology

The idea of shear-bolt connectors goes back to the beginning of the 1980s, when companies introduced low-voltage bolted connectors, which could be torqued to a precise value. The solution to that innovation was how to use a reliable, best-fit clamping force that was not excessively tight or loose.

In these early designs, the power needed was preset: each bolts were machined in such a way that once it was tightened to the desired power level, it would cut itself off after a set point. This made sure that the installer applied the right amount of clamping force each time, irrespective of experience, eliminating installation errors.

On the success of the low-voltage systems, engineers used shear-bolt technology with low-voltage cables, followed by expansion to medium-voltage. The problem with MV systems (typically to 42 kV) was more rigorous: connectors must contain no protruding, sheared bolt heads or sharp edges, and must be compatible with sheaths, insulation, and various other elements.

Design Principles and Key Advantages

1. Pre-Set Torque and Controlled Shearing

The shear-bolt technology is based on the controlled-torque bolt. The installation is tightened by pressing a bolt acting on the conductor. When the right amount of torque is attained, the head of the bolt shears off. This provides two great advantages:

- Constant compressive force: All installations produce compressive right forces.

- No risk of over-tightening: To avoid damaging the conductor or connector, it is not possible to tighten the bolt head any further after shearing.

2. Stepless / Multiple Shear Points

Current connectors are frequently of shear-bolt design, with no fixed notch, or with more than one shear point, such that:

- The edges of the bolt are never jagged, as they are always cut at right angles to the connector body.

- Due to the defined nature of torque behavior, a connector body having many useful dimensions and materials can be supported.

3. Smooth, Concentric Connector Body

A smooth external profile is important in MV applications. The connector shear-bolts are designed in such a way that once installed, they possess:

- An outer surface that is rounded and equal.

- No sticking out bolt heads that can be disruptive to the process of layering sleeves, insulation, or other accessories.

- Sharp corners are prevented by a smooth finish.

4. Material and Corrosion Resistance

Connector bodies are normally composed of high-tension aluminum alloy, frequently plated with tin to inhibit oxidation and corrosion. Special aluminum alloy is used in the shear bolts, and in some cases, polymer compensating rings are used. Internal (the area where the conductor is to be laid down) is grooved to enhance contact, reduce oxidation, and enhance long-term electrical stability.

See also: Where to Find the Best Sharjah Family Hotels for a Relaxed Staycation

5. Ease and Speed of Installation

As the installation of the shear-bolt connector does not need any crimping tool or special dies, it can be installed with a simple hex key (or socket wrench). This enables installation to be faster, less labor-intensive, and less operator skill.

Features for MV Performance

Smooth, Concentric Body Design

In MV applications, the connector must be uniform, of a rounded shape, so that insulation accessories fit the connector properly. In the current implementation, there are modern shear-bolt connectors, where all of the bolt heads slide into the connector body.

Tin-Plated High-Conductivity Alloy

In connector bodies, the tin-plated aluminum alloy is normally utilized to resist corrosion effects, conductivity, and galvanic effects when used with copper conductors.

Internal Serrations

The internal surface is, in many cases, grooved or serrated. These grooves:

- Improve mechanical grip

- Enhance the contact area

- Decrease loading resistance.

- Assistance stabilizing thermal siloing.

Multiple or Bolt System Dual systems

Designs in medium-voltages use two or more shear bolts. This ensures even compression along the conductor, and this is critical in connections that are subject to high thermal and mechanical forces.

Reliability and Impact on Network Stability

The use of shear-bolt connectors in MV networks has several benefits in reliability:

Low Chance of Bad Connections

Since torque is automatically adjusted (through shearing of the bolt), there is a reduced variation in the tightness of each connection. This avoids under-torqued joints (they may possess high resistance) and over-torqued joints (which may damage conductors).

Improved Contact Longevity

Grooved contact surface, tin plating, and stable compression imply that electrical contact is solid over time, even without thermal cycling and mechanical deformation.

Simplified Stocking and Specification

Only one connector model is frequently available in a large number of conductor sizes and materials. Installers and utilities have the opportunity to reduce inventory and the chance of selecting incorrect parts.

Field-Friendly Installation

It can be installed using only a hex key or socket and does not require investment in crimp tools, as well as it can be deployed faster in tight or remote locations. It also lowers the level of training required by field technicians.

Enhanced Safety

This is achieved by a shearing bolt head that forms an inbuilt torque limiter. This eliminates chances of overtightening that may cause mechanical reliability or connectors and conductors.

Normative Compliance and Quality

A considerable number of shear-bolt connectors are type tested to international standards (including IEC 61238-1), and cover strict requirements of short-circuit operation, aging, mechanical loading, and other factors.

Applications in Modern Power Distribution

Medium-Voltage Terminations

Shear-bolt lugs are successfully employed in MV terminations of substations as well as industrial plants and city underground systems.

Splicing and Jointing

The use of shear-bolt connectors in joints is necessary because:

- Repair sleeves

- Straight joints

- Branch connections

Renewable and Distributed Energy Systems

The increase in the development of solar farms, wind, and distributed generation has driven the need to have easy-to-install, reliable MV connectors.

Conclusion

MV Shear-bolt screw connectors are an established, well-trusted solution for power distribution systems. Their pre-torque feature, reliable shear-off approach, and simple, compact design make field installers’ jobs easier by improving time and minimizing risk in making a reliable electrical connection. Usage of shear-bolt connectors has strengthened the reliability of the grid, minimized installer errors, and simplified operational units.